Indonesia has inaugurated Southeast Asia’s first EV battery manufacturing plant in Karawang, West Java.

In a bold move that signals Indonesia’s ambition to become a major player in the global electric vehicle (EV) market, the country has inaugurated Southeast Asia’s first EV battery manufacturing plant in Karawang, West Java. The $1 billion facility, a joint venture between South Korea’s Hyundai Motor Group, LG Energy Solution, and Indonesia Battery Corporation, marks a significant milestone in Indonesia’s strategy to leverage its vast nickel reserves and challenge the existing global EV supply chain.

RELEVANT SUSTAINABLE GOALS

Southeast Asia’s first EV battery plant

The plant, operated by HLI Green Power, is set to produce 10 gigawatt-hours (GWh) of battery cells annually, enough to power 150,000 electric vehicles. Plans are already in motion to double this capacity to 20 GWh with an additional $2 billion investment, underscoring the scale of Indonesia’s EV aspirations.

“Mineral resources of this nation, such as iron and nickel, are important components in batteries that will mobilize millions of EVs globally,” said Hyundai Motor Group Executive Chair Euisun Chung at the opening ceremony, highlighting the strategic importance of Indonesia’s natural resources in the global EV supply chain.

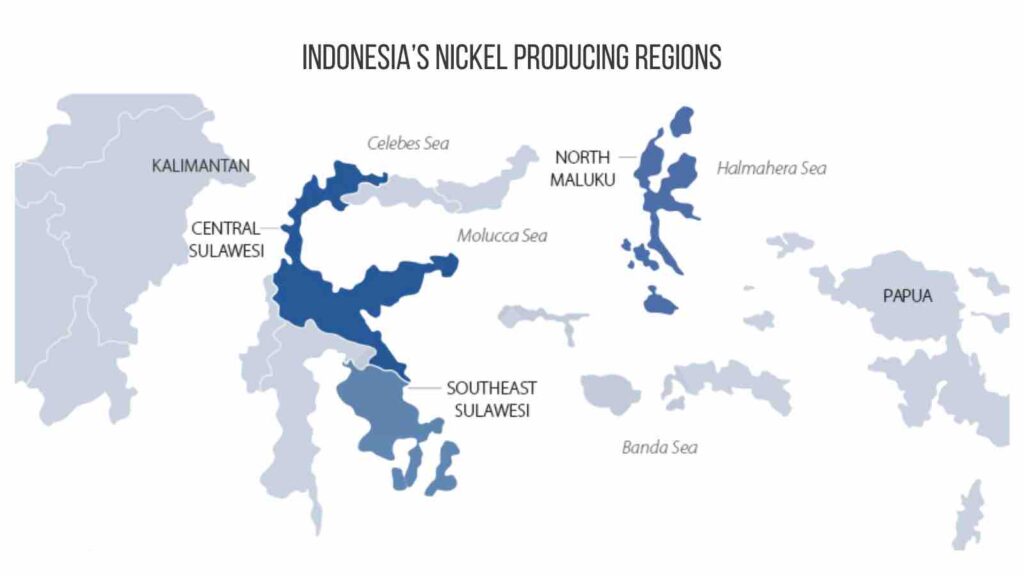

The plant’s launch is part of a larger $9.8 billion deal signed in 2020 between Indonesia and LG to develop a comprehensive EV ecosystem in the country. This ambitious project aligns with Indonesia’s goal to become one of the world’s top three EV battery producers by 2027, capitalizing on its position as the world’s largest nickel reserve holder and producer of an estimated 40% of global nickel in 2023.

Strengthening Indonesia’s Position in the EV Market

Indonesia’s strategy, however, is not without its challenges. The country’s 2020 ban on raw nickel exports, aimed at encouraging local processing and value addition, has raised eyebrows in international trade circles. Moreover, the rising tide of economic nationalism and the fragmentation of global supply chains present potential hurdles to Indonesia’s EV dreams.

Coordinating Minister for Maritime Affairs and Investment, Luhut Binsar Pandjaitan, remains optimistic. At the ceremony, he emphasized Indonesia’s readiness to become a key player in the global EV supply chain, citing potential benefits including reduced carbon emissions and improved air quality for Indonesians.

The plant’s integration with Hyundai’s local auto factory, which plans to produce 50,000 Kona Electric SUVs annually using Indonesian-made batteries, demonstrates the potential for a vertically integrated EV industry in the country. This model could serve as a template for other resource-rich nations looking to move up the value chain in the green technology sector.

The inauguration of this plant is more than just an industrial milestone; it’s a statement of intent from Indonesia. As the world grapples with the urgent need for sustainable transportation solutions, Indonesia’s bold move into EV battery production could mark the beginning of a new chapter in the global race for green technology supremacy.

You may also be interested in :

PLN’s Innovation: Transforming Electric Poles Into EV Charging Stations Across Jakarta