Pyrolysis excels at managing plastic and tire waste, two of the world’s most persistent environmental challenges.

RELEVANT SUSTAINABLE GOALS

In an era dominated by discussions on sustainable development and climate resilience, pyrolysis emerges as a transformative solution. Unlike traditional waste management techniques such as landfills and incineration, pyrolysis converts waste into valuable byproducts like fuel, biochar, and gases—all while minimizing emissions. Despite its immense potential, this technology remains underutilized and misunderstood.

What Is Pyrolysis?

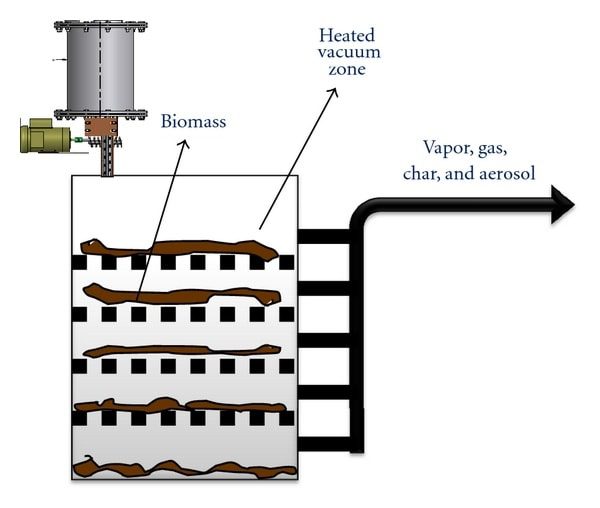

The term “pyrolysis” originates from the Greek words pyro (fire) and lysis (separating). It refers to heating organic material in an oxygen-free environment, which prevents combustion. Instead, the process breaks down large molecules into smaller ones, producing:

- Biochar: A solid residue ideal for soil amendment.

- Pyrolysis Oil: A liquid fuel with 50-70% of crude oil’s energy value, which can be upgraded to biodiesel.

- Gases: Including hydrogen, methane, and carbon monoxide, which can power the pyrolysis process itself.

With catalysts like natural zeolites, the efficiency of pyrolysis improves further, reducing operating temperatures and enhancing output quality.

Pyrolysis in Action: A Circular Approach

One community in Cupuwatu 2, Yogyakarta, exemplifies pyrolysis’s potential. With a machine provided by the Get Plastic Indonesia Foundation, residents can convert one kilogram of plastic waste into a liter of high-quality diesel or gasoline. This small-scale innovation addresses both waste management and local energy needs, showcasing pyrolysis’s adaptability and impact.

While pyrolysis offers a cleaner alternative to traditional methods, it is not without limitations:

- Energy Intensity: Heating feedstock to temperatures exceeding 450ºC requires significant energy. However, using pyrolysis-generated gases to power the process creates a self-sustaining system.

- Feedstock Variability: The diverse composition of waste inputs can result in inconsistent outputs, particularly in large-scale operations.

- Criticism of Carbon Outputs: Though pyrolysis repurposes waste, burning its fuel products still generates greenhouse gases, delaying the shift to a zero-carbon infrastructure.

Despite these challenges, proponents argue that the benefits outweigh the downsides. Recycling even a fraction of waste reduces landfill dependence and ocean pollution.

The Case for Pyrolysis in Modern Waste Management

Imagine a landfill equipped with pyrolyzers. Recyclable materials like metals and glass could be separated and sold, while organic waste undergoes pyrolysis to produce fuels and biochar. This circular system minimizes vermin, leachate, and methane emissions, transforming traditional waste sites into hubs of resource recovery.

Countries like Bangladesh, Indonesia, and Vietnam are leading the way by integrating pyrolysis into community-level waste management. For instance, floating pyrolysis units in flood-prone regions could revolutionize both energy production and waste disposal. Meanwhile, researchers continue to refine catalysts and processes to expand pyrolysis’s capabilities.

While critics highlight its imperfections, pyrolysis represents a significant step toward sustainability. With global waste generation expected to surge and climate challenges intensifying, delaying action is not an option. As one expert aptly noted, “Even if flawed, pyrolysis offers solutions we can deploy now, as part of a broader transition toward a circular economy.”

Pyrolysis is more than a technology; it’s a vision for a cleaner, more resilient future. Its widespread adoption could redefine how humanity views waste—not as a problem, but as a resource.

You may also be interested in :

From Bali and Yogyakarta : Transforming Plastic Waste to Fuel